Lithium-ion batteries: powering the future

Batteries are essential in the global energy transition. They enable decarbonization through electrification and are used for storing renewable energy. How does a battery work?

![]()

header.search.error

Batteries are essential in the global energy transition. They enable decarbonization through electrification and are used for storing renewable energy. How does a battery work?

Key takeaways

One of the main drivers of the energy transition is decarbonization through electrification. Since batteries play a key role in electrification, they have become essential to the global energy transition. They are now ubiquitous, powering everything from mobile phones to electric vehicles (EVs) and storing renewable energy in order to balance the grid. But how does a battery work and what are the technological developments in the battery sector?

A brief history of battery technology

Batteries convert chemical energy into electrical energy and vice versa. The first battery was described by Italian physicist Alessandro Volta in 1800.1 His “voltaic pile,” a stack of copper and zinc plates separated by paper disks or cloth soaked in brine, was able to produce a steady current for about an hour and marked the beginning of the evolution of battery technology. Notably, Volta also gave his name to the unit of electromotive force, the volt (V). The “wet cells”, such as the British “Daniell cell” (1836), that followed the voltaic pile were slightly more stable but were also prone to leakage, spillage, and short circuiting. The “dry cell” was invented by the German scientist Carl Gassner in 1886. Although it still contained liquids, it was much safer to handle and had a longer battery life.2 It was also fit for mass production: the slightly adapted “Columbia dry cell” was first marketed by the US National Carbon Company in 1896.3 The invention of the nickel cadmium rechargeable battery by Waldemar Jungner from Sweden in 1899 came next, followed by the development of lithium batteries from the 1970s onwards.

Breakthroughs in lithium ion batteries

Due to its chemical properties, such as its low density, high electrochemical potential, and decent energy to weight ratio, lithium4 was thought to be a good battery material. The road to lithium batteries was paved early last century, with Gilbert Newton Lewis experimenting with the metal in 1912. But it was not until the 1980s that real technological breakthroughs in lithium ion batteries were reached. The lithium battery as we know it today was born in 1979, and in 2019 Stanley Whittingham, John Goodenough, and Akira Yoshino won the Nobel Prize in Chemistry for their contributions to the development of the fast charging, high energy density, lightweight lithium ion (or Li ion) battery.5

How does a lithium-ion battery work?

A battery consists of four components: a cathode (negative electrode), an anode (positive electrode), a separator creating a barrier between them, and an electrolyte serving as a medium that enables an electric charge to flow between the cathode and the anode. When a battery is discharging, for instance to supply electric current to an attached device or electric vehicle, positively charged lithium ions travel from the anode to the cathode, and negatively charged electrons move in the opposite direction. Conversely, when a battery is charging, lithium ions flow from the cathode to the anode, causing electrons to move from the anode to the cathode. The electrolyte serves as an ion-conducting material, while the separator is an ultra-thin, porous membrane that isolates the cathode material from the anode material to prevent short-circuiting.

The choice of materials in lithium ion batteries matters

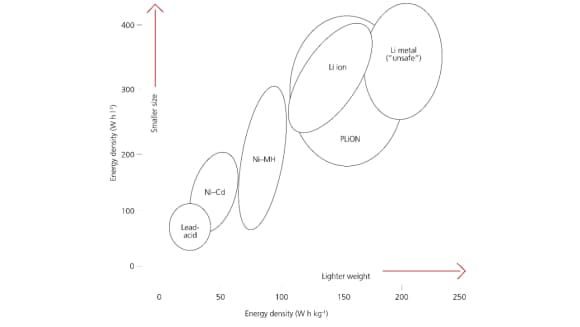

The cathode and anode are the most important components of a lithium ion battery, which determine properties such as the battery’s voltage (electric potential, measured in volts), power density (how quickly a device can charge and discharge, watts6 per kg or W/kg), energy density (how much energy is stored in the battery, watt-hours/kg or Wh/kg) and safety characteristics.

Until recently, anodes have mostly been made of graphite and hence they have been light in weight. Since cathode materials are the largest and heaviest part of a battery, with a cathode-anode mass ratio of 3:1 or 4:1, efforts to improve energy density in batteries (and to lower their cost) have predominantly been focused on developing the cathode. The most common cathode types are LCO (lithium cobalt oxide), LMO (lithium manganese oxide), LFP (lithium iron phosphate), NCM (lithium cobalt manganese), and NCA (nickel cobalt aluminum).

In terms | In terms | LCO | LCO | LMO | LMO | LFP | LFP | NCM | NCM | NCA | NCA |

|---|---|---|---|---|---|---|---|---|---|---|---|

In terms | Chemical formula | LCO | LiCoO2 | LMO | LiMn2O4 | LFP | LiFePO4 | NCM | LiNiMnCoO2 | NCA | LiNiCoAlO2 |

In terms | Energy density | LCO | High | LMO | Medium | LFP | Low | NCM | High | NCA | High |

In terms | Safety | LCO | Low | LMO | High | LFP | High | NCM | Medium | NCA | Low |

In terms | Life span | LCO | High | LMO | Low | LFP | High | NCM | Medium | NCA | High |

In terms | Cost | LCO | High | LMO | Low | LFP | Low | NCM | Medium | NCA | Medium |

In terms | Power output | LCO | Medium–High | LMO | High | LFP | Low | NCM | Low / Medium | NCA | High |

Trends in lithium ion battery chemistry

Traditionally, NCM type batteries dominated the global battery market, peaking at 63% of global battery supply in 2022.7 Strong growth in battery demand for both energy storage systems and electric vehicles has triggered burgeoning demand for critical materials, such as nickel, cobalt, lithium, and manganese, driving up commodity prices. Higher input prices combined with the ongoing quest for higher energy density have led to the development of new battery technologies. As Chinese lower end mass produced EV production took off in recent years, a cheaper LFP battery cathode technology has begun to increase its market share, seeing global penetration rise from 15% in 2015 to 37% in 2022. In China itself, LFP is already the leading battery technology, reaching a 55% share in passenger EVs and a 67% share in commercial EVs in 2022.7

On the other hand, in NMC technology, the trend is toward high nickel chemistries, which means increasing the nickel content of the cathode to over 90% and lowering the cobalt and manganese content to below 10%. NMC cathode composition is represented by NMCxyz, where xyz are the relative proportions of cathode material: x denotes the nickel content, y the manganese content, z the cobalt content, and x+y+z = 10. Nickel based chemistries are expected to be dominated by NMC9.5.5 cathodes and upward in the future, as the industry increasingly looks to reduce cobalt content in batteries.

Electricity grids are becoming larger and more complex, driving record growth in demand for energy storage systems,8 while on the transportation side, decreasing range anxiety and the rollout of fast charging networks are driving EV penetration, with global EV share of new vehicle sales expected to rise from 14% in 2022 to 30% in 2026.9

Battery technology roadmap

Endeavors to continually improve battery performance characteristics, such as safety, energy density, lifetime, and charging speed, are a driving force behind rapid advances in battery technology. Costs and sustainability considerations, especially related to ecological footprint concerns and human rights violations,10 are having a significant impact on the technology roadmap and materials chosen as ingredients for future lithium ion batteries. Given graphite’s energy intense production process, this anode material is being replaced by cheaper and more environmentally friendly silicon anodes.11 Sodium ion batteries12 are gaining popularity. The working principle underlying sodium ion batteries and lithium ion batteries is very similar, but sodium ion batteries use sodium ions instead of lithium ions to shuttle back and forth between the anode and cathode, which are both made of a cheaper material than in a Li ion battery. They are safer too, and since natrium (sodium) is quite abundant, raw materials are cheaper and more environmentally friendly to obtain. Yet, sodium ion technology still has its drawbacks in terms of energy density and cycle life.

Solid state batteries could change the game, but a technological breakthrough is needed

While many new types of batteries are under development, the biggest near term breakthrough would be commercial mass production of solid state batteries (SSBs). Cathode and anode materials in a solid state battery are similar to those in a Li on battery; however, the electrolyte material is a solid polymer or ceramic. This eliminates the need for liquid electrolytes, which are often the cause of flammability, degradation, and lower cycle performance.13 Since the electrolyte is an ion conductor in a solid form, there is no need for a separator, which frees up space in the battery for more active material, thereby significantly increasing the battery energy density, charge rate, and cycle life, and ultimately improving its cost as well. SSBs will also be much easier to recycle, which gives them an environmental edge.14 Many auto manufacturers and battery manufacturers are joining research and development efforts in the race to develop solid state batteries.15 As a result, battery technology looks set to keep charging ahead.

CFA, Senior portfolio manager, Thematic Equities

Dirk Hoozemans (MA, CFA, ESG CFA), Director, is Lead Portfolio Manager of the Energy Evolution strategy. In 2022, he joined Credit Suisse Asset Management, now part of UBS Group, from Triodos Investment Management, where he was fund manager of a global small- and mid-cap-focused thematic impact strategy and responsible for outlining a new impact-driven investment process, including ESG integration and active ownership policies. Prior to that, Dirk held various portfolio management positions at Robeco Asset Management, including portfolio manager of a global energy strategy. Dirk holds a master’s degree in Econometrics from Tilburg University, The Netherlands, is a CFA charterholder, and has obtained the CFA Institute Certificate in ESG Investing.